We specified, designed and realised a solution for the automated assembly of X-ray detectors. Together with our customer we made a thorough evaluation of the process requirements, requested flexibility and operator interaction. Based on these requirements we have designed a, cleanroom class ISO 5 compatible, solution for the assembly of the tile-arrays. Within this solution the tiles are fully automated supplied, aligned and glued together within a few micro meter accuracy.

In a second station the tile stack is assembled in the full product assembly. This step involves a highly controlled robotized dispense and curing station. During the assembly various operator interactions are required for process and product inspections, various process steps are inline checked by measurement and all data is stored ensuring full product traceability.

Our solution enables the customer full control to all process parameters in a recipe based system. This enables quick interchange to various product types as well as flexibility in the production process without complex system and hardware changes.

Other competences used in this solution:

- Robotic Handling

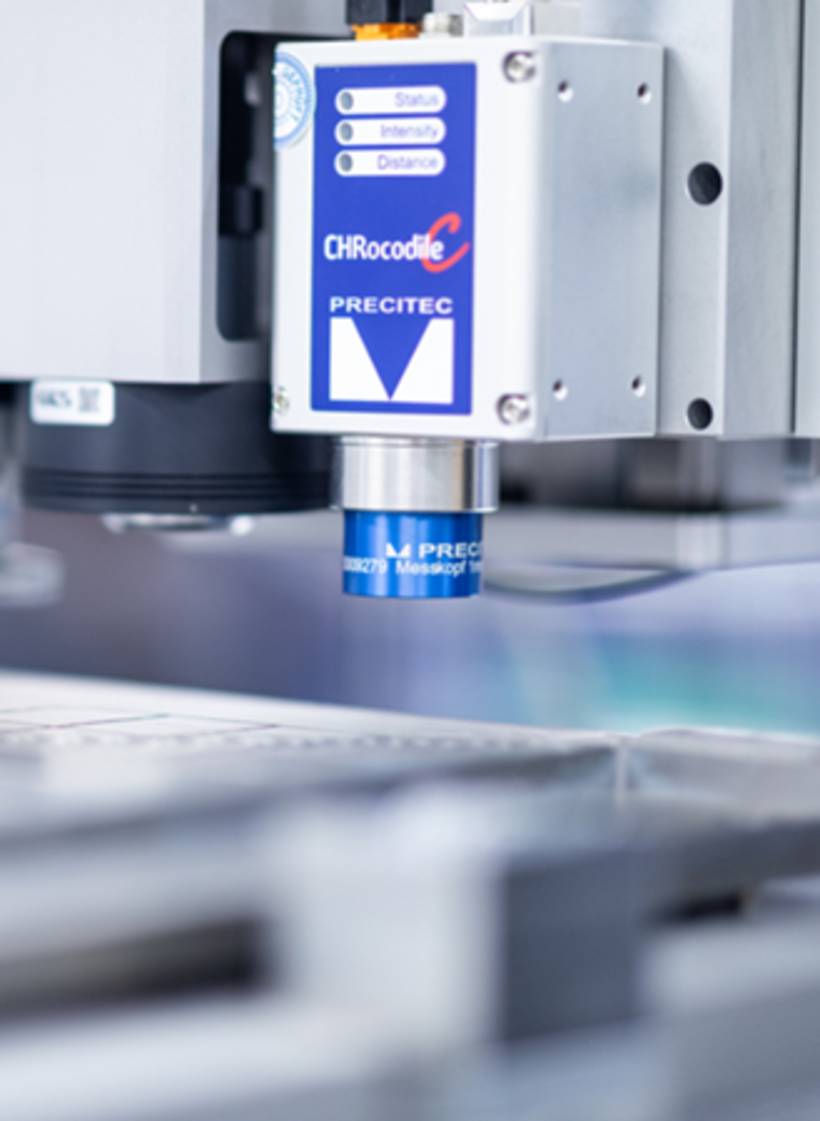

- High Precision assembly

- Accurate Handling systems

- Vision

- Design and realisation for cleanroom ISO 5 environment