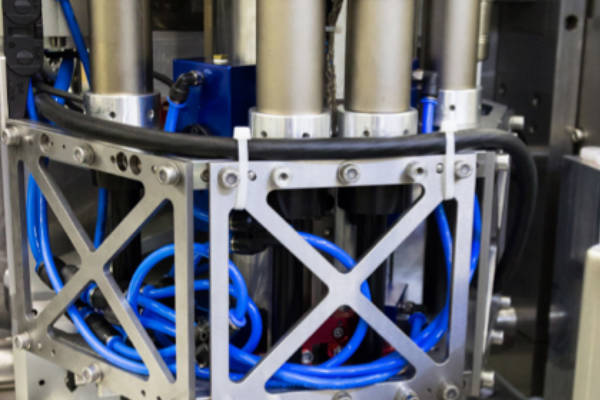

Together with our customer we made an evaluation on the process demands including process control possibilities. Based on these steps we designed an realized a processing cell which enables very accurate product processing. The product is supplied an in several processing stations an ID code is read, the products is centered, processed, cleaned and checked. Several of these processing stations work in-line for increasing product output.

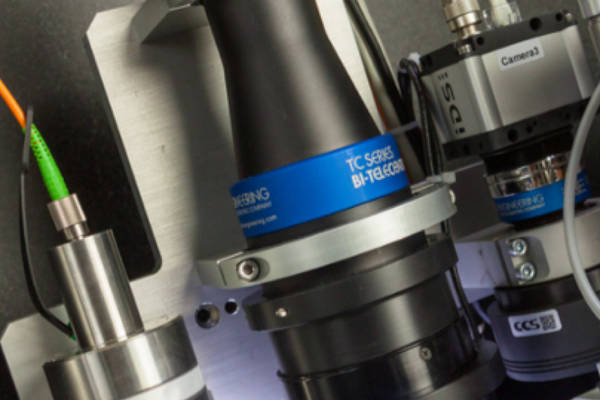

Together with the processing stations we realized a semi-inline measurement station which randomly measures products from one of the production cells. Within this cell various parameters are measured with less than micrometer accuracy.

Other competences used in this solution:

- Robotic Handling

- High Precision assembly

- Accurate Handling systems

- Vision