FMI is a full service contract manufacturer. We work in close cooperation together with our customers in order to become partners. Starting from co-engineering on NPI's, moving forward to serial production we deliver your product.

Quality

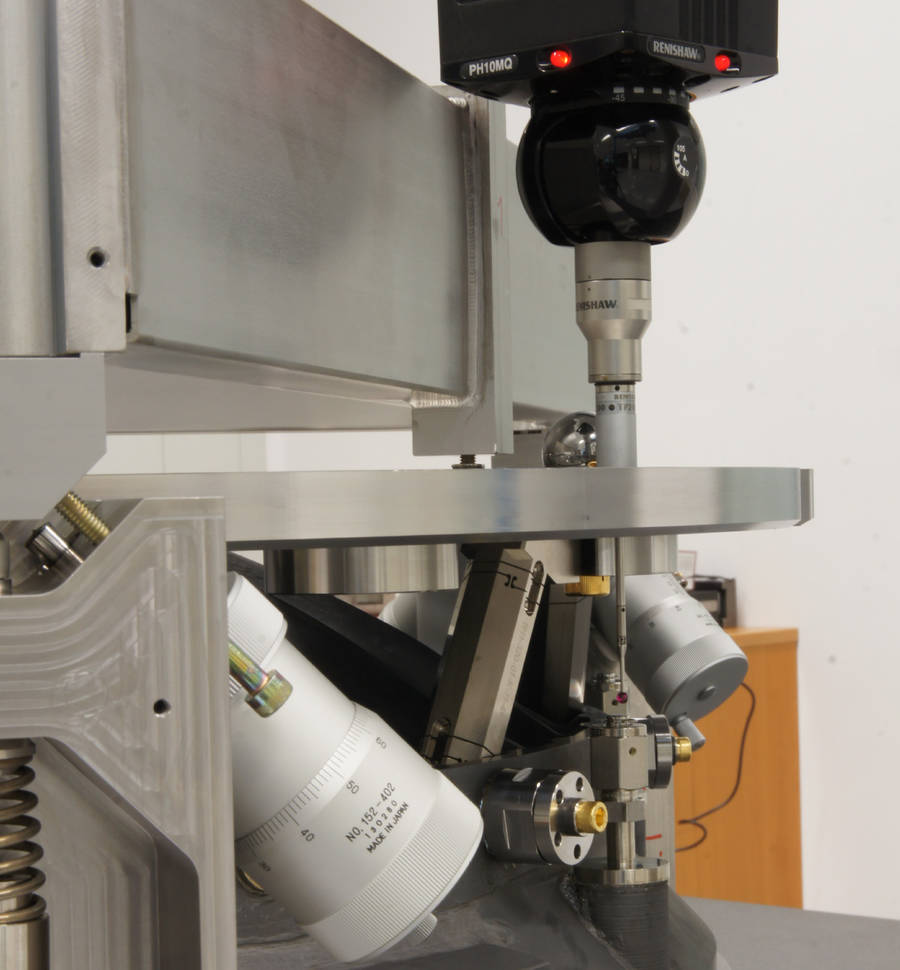

Given the accuracy required by our customers we continuously monitor and safeguard the quality of our processes and products. We have some of the most accurate measuring equipment. In a specially conditioned environment, our coordinate measuring machines are able to carry out measurements with an accuracy of up to 0,0003 mm.

Within FMI, all of our processes are carried out under the ISO 9001-2015 standards.

Make-ability

The key factor that determines success in our ability to make a product, keep costs to a minimum and ensure on-time delivery, is the extensive cooperation between our engineers and our production teams. As FMI has both 'under one roof', our lines of communication can be kept short and changes can be made quickly and easily.

By combining advanced technologies with our regular production processes, we are a valuable partner for prototypes, first-series leading to volume production.

Prototyping

To speed up the process from design to finished product and shorten the time to market quick prototypes are essential.

Serial Production

At our CNC machining centre we are equipped with the very latest CNC turning & milling machines, robots and tooling equipment. With our high degree of automation, our machining processes are able to run 24/7.

Assembly

In cooperation with FMI Mechatronics we are specialised in producing integrated products that combine mechanical, electrical and electronic systems & controls.

Clean packaging

For the assembly of modules and the integration of systems we have several assembly facilities. When clean assembly is required, we have ISO Class 6 & ISO Class 7 clean rooms.

Supply Chain

We offer comprehensive supply chain management whereby we organise and manage the complete value chain for our customers.

Our FMI competences

At our CNC machining centres, we use the very latest in CNC turning & milling machinery, EDM machines, robots and equipment. With our high degree of automation, our machining processes are able to run 24/7, mostly without any human intervention. We also lead the way when it comes to innovative technologies such as 3D metal printing, Computer Aided Manufacturing and robotics.